Buy Sales plastics compactor and heavy duty granulator pet Price

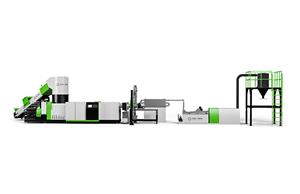

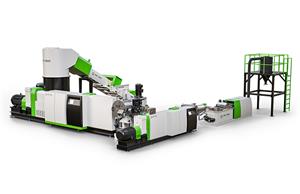

plastics compactor and heavy duty granulator pet

plastics compactor and granulator

The assets are currently located in its 178,000-square-foot facility on Cedar Street, Fremont, about 38 miles east of Toledo, Ohio. The plastics company is based in Willowbrook, Illinois. Location is being sold to another operator as an ongoing facility.

"Through this sale, manufacturers can obtain, auction prices, blow molding machinery and related equipment processing capacity of 20 million pounds of plastic gas tanks, fuel tanks, kayaks, playground equipment, portable toilets and other products," said John Coelho, a senior executive in tiger's commercial and industrial division.

Charles Winternitz, President of Loeb Winternitz, said, "The Fremont plant has a wide range of well-maintained and highly productive blow molding equipment and ancillary assets. "This is a huge opportunity for direct competitors and other manufacturers in the plastics industry to purchase primary production equipment and/or ancillary assets, resulting in significant new cost savings." We are very happy to be part of this project. "

The machines on sale include a huge 10-pound accumulator blowmolding machine. 100 pounds. Manufactured by Davis Standard/Sterling, Hartig and Krupp Kautex.

Auxiliary equipment includes fanaco 6-axis robots, ball-making production lines, granulators with blowers and cyclones, buffer silos, vacuum loaders, scales, leak detectors, slant conveyors and conveyors, quality control laboratories, a large number of spare parts and maintenance accessories.

Buy heavy duty granualator

Plant support equipment includes Quincy and LeRoy rotary screw air compressors, air dryers and chillers, galvanized steel storage tanks with blowers, rail vehicle unloading systems, Lantai and highlight automatic pallet wrappers, shrink tunnels, shrink tunnels, and more.

The founders of rPlanet Earth say that by using efficient and technologically advanced equipment, they will be able to eliminate costly intermediate-stage production steps, supplier mark-ups, and transportation costs, which will enable rPlanet Earth to deliver high-quality, Competitively priced food grade rPET packaging.

The company's plant uses a food-grade scale production system from Krones, With a North American office in Franklin, Wisconsin. It also has a front-end sorting system, provided by the Bulk Processing System (BHS) in Eugene, Oregon, which includes five optical scanners from BHS subsidiary NRT to remove metal, mixed plastics and color PET, and actively classify PET. The sorting system also includes a Max-AI AQC-2 robot sorter for final quality control. The plant's front-end sorting system processes nearly 8 tons of B-class (roadside) PET bags per hour, which are purchased by rPlanet Earth from the Material Storion Facility (MRFs) in California.

Bob David Duke, co-chief executive of rPlanet Earth, said: "We will introduce technology to improve the way pets are recycled after consumption. "Because of the way we assemble our plants, we will have the lowest carbon footprint of all packaging on the market. "

David Duke and his business partner and co-CEO Joe Ross founded the company about six years ago. Ross is a packaging engineer with a background in designing, manufacturing and selling food and beverage products, while David Duke has a background in finance and has held leadership positions at several large financial services companies.

Sales granulator pet Price

David Duke says their business partners start by raising money and reviewing equipment suppliers. They bought what they considered state-of-the-art equipment to help rPlanet Earth produce rPET packaging to meet the needs of consumer packaging companies in food, beverage, cosmetics, household products and other industries.

Pietro Bortone, plant manager at Presenzano Ferrarelle, said: "Through our new recycling plant, we have taken another step forward in the environmentally friendly attitude we have pursued over the past few years. He added: "Ferrarel is already focusing on several social and cultural international projects, and it is protecting its territory by increasing productivity, supporting people's employment, reducing litter and polluting." "

According to AMUT, Ferrarelle "represents best practices for the circular economy." It was one of the first european companies to dabble in the beverage industry, and the company decided to end the CYCLE of PET bottle processing through internal processing. "

In the factory, bundles of bottles were opened and delivered to the feeder. Before the cleaning phase, the detector performs the initial positive selection to separate the bottle from the contaminant. The system allows the use of PET bottle bags that are not thoroughly classified, even from packages with a considerable amount of mixed material.